About us

The registered office of ASFOR Poznański sp.j. is located in Chełmek, ul. Mickiewicza 46, Oświęcimski District (Małopolskie Province). Chełmek is a city with footwear history and traditions, it is a so-called former capital of shoes in Poland.

History

The beginnings of the company’s activity date back to 1992. ASFOR was founded by Stanisław Poznański – a professional in the footwear industry, a long-term employee of Południowe Zakłady Przemysłu Skórzanego [Southern Leather Industry Factory] and Zakłady Urządzeń Technicznych TECHNOSKÓR [Technical Equipment Factory] in Chełmek. His professionalism and the ability in effective and efficient managing are reflected today in a stable and prosperous company. ASFOR is a company with family traditions. At present, the company is owned by its founder’s sons: Rafał and Marek Poznański. They have acquired many years of their father’s experience adding knowledge and modern thinking, dynamics and effective management. They have created a modern, well-managed enterprise, meeting the expectations of even the most demanding Customers at home and abroad. Their market strategy is based on a constant improvement of the quality of offered products, and individual approach to Customers.

Our products and offers

ASFOR Poznański sp.j. is an enterprise specialized in production of molds for footwear soles. The services offered by the company in the field of design, construction of footwear molds and instruments are a guarantee of quality and reliability which are reflected in Customer trust. ASFOR constitutes a perfect combination of features of an enterprise with many years of experience and modern management style.

TECHNOLOGY

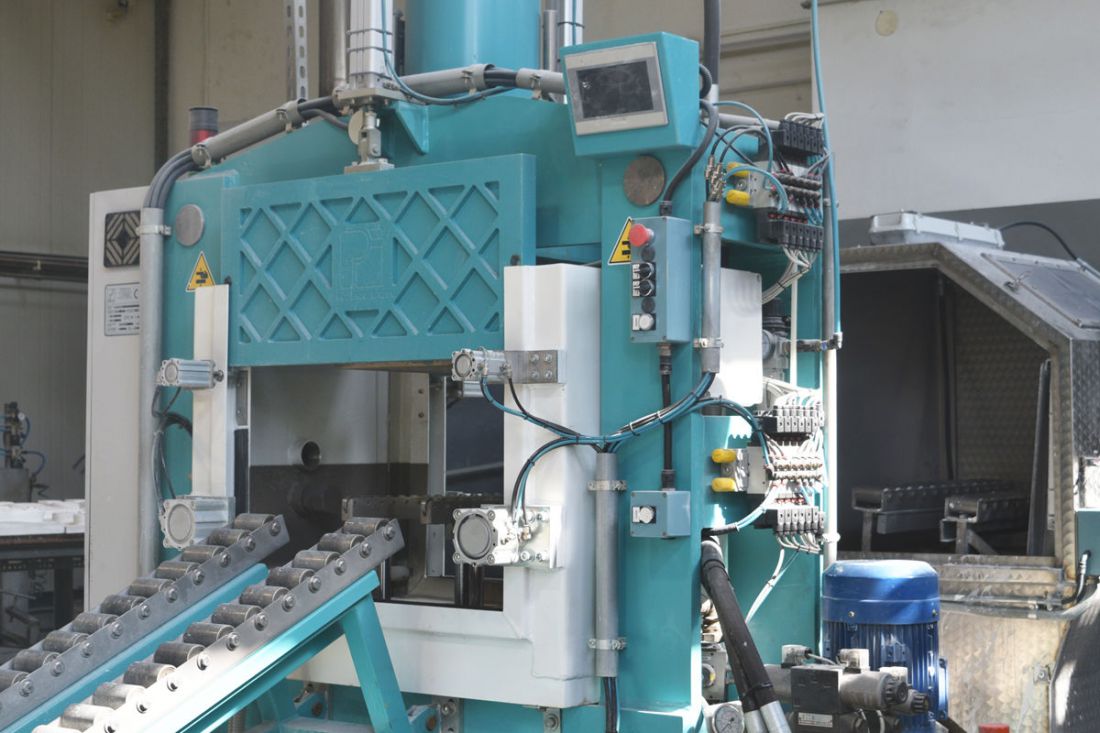

ASFOR Poznański sp.j. is specialized mainly in manufacturing molds used for producing footwear soles. The basic material used in mold manufacturing is aluminum. At the Customer’s request, the molds can be made also of more durable materials such as duralumin. The main methods used are machining, casting and electrical discharge machining. The main operations conducted during production are: cutting, milling, drilling, turning, engraving, and polishing. Particular components of the molds, including matrices, stamps, inserts, ejectors, are made between the operations in the following halls: CNC machines, calibrating shop, pattern shop, foundry, lathes and electrical discharge machine hall, and locksmith’s shop.

Market Policy

The production technology used by the company is characterized by pioneering and innovations. It is based on parametric design during which an advanced CAD/CAM system, a measuring arm with a contactless laser head, and a coordinate measuring machine are used. It has one of the few footwear molds foundry in Poland. Moreover, the company has a modern machine park equipped with many units, including CNC machining centers. All this establishes a compatible system that enables the implementation of any kind of “from concept to product” projects.

ASFOR conducts an expansive market policy that is implemented through the introduction of modern solutions and activities on further education of the employees. It employs about 60 people in total. The staff constitutes a good team of highly experienced and qualified employees. Involvement in a maximal use of acquired skills and potential are reflected in the highest standard of the services and products offered.